Processing Capabilities

Petersen Inc. offers turn-key solutions for your needs by completely managing all aspects of even the most complex project. We offer state-of-the art facilities for all your plate processing needs at one location, providing complete resolutions.

Our in-house fabrication processes include:

Design Engineering I Machining I Advanced Manufacturing I Paint, Blast, Powder Coat I Tool Build I Forming I Rolling I HD Plasma Cut I Waterjet I Design I Machine I Manufacture I Blanking

Waterjet

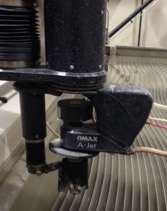

Petersen Inc. offers three OMAX JetMachining Centers. Below is a comparison of two of our state-of-the-art waterjets.

OMAX 120X

- 2 cutting heads

- Head 1: 3-axis cutting head with terrain follower

- Head 2: 3-axis cutting head with terrain follower

- Minimum Spacing = 19 inches

OMAX 160X

- 2 cutting heads

- Head 1: A-Jet 5-axis cutting head with terrain follower

- Maximum Cutting Angle = 59.5 degrees

- Head 2: 3-axis cutting head with terrain follower

- Minimum Spacing = 24 inches

- 2D Cutting

Rolling

Petersen Inc.’s in-house rolling capabilities range from ¼-inch to 2 inches thick by 12 feet wide rolling- up to 20 feet in diameter. Our rolls are equipped with cone-rolling attachments. We are capable of rolling up to 8-foot bar and also offer angle and bar rolling. Petersen Inc. has sold and produced over 600 ASME code vessels.

Paint/Blast/Coat

Petersen offers six modern paint booths. Our paint bays range from small 10 x 20-feet up to large 17 x 60-feet. Our personnel are experienced in all paint types and systems for industrial applications. We also offer a full service powder coat line complete with phosphate washing to curing ovens. We have powder coated over 20,000 products through our system.

Our material prep and blasting operations include steel shot grit blasting, glass bead blasting, garnet blasting and sand blasting. Our personnel are well qualified and experienced in all of our in-house methods of material preparation.

Stress Relieve

Our on-site stress relieving oven measures 28 feet in diameter and 14 feet tall. We are capable of lifting the oven off the part so that we can use the entire footprint. The oven is also equipped with three 6-million BTU natural gas burners, and temperatures range from 0 to 1650 degrees Fahrenheit. Our system is fully calibrated. Petersen Inc. has been providing stress relieving services for over 25 years.

Burning and Plasma Cutting

Petersen Inc.’s burning and hi-definition plasma cutting capabilities operate over a table that is 12 feet wide x 44 feet long. We are capable of multiple torch burning. Our operation is automated and CNC controlled to provide the highest quality and efficiencies available in the industry.

Forming

Petersen Inc. is equipped with modern, state-of-the-art equipment including a wide range of plate rolls and brake presses. We have a 35-ton, 400-ton and 700-ton brake press. Our bed lengths range from 6 to 24 feet, and all of our brake presses are equipped with a wide variety of tooling. Petersen Inc. has been in the brake press business for over 30 years. These machines are very well equipped with skilled operators that run them.